How Mouse Sensors Track Movement: Sensor Mechanics Explained

Ever wonder how computer mice work beneath the sleek exteriors? The answer lies in the sophisticated mouse sensor technology that translates your physical movements into on-screen precision. Understanding these components isn't just for tech enthusiasts (it's crucial for gamers needing pixel-perfect aim or professionals requiring seamless cursor control for hours). In this QC-aware analysis, I'll break down exactly how these sensors operate, why surface compatibility matters, and where marketing claims diverge from real-world performance.

The Core Mechanics: How Mouse Sensors Actually Work

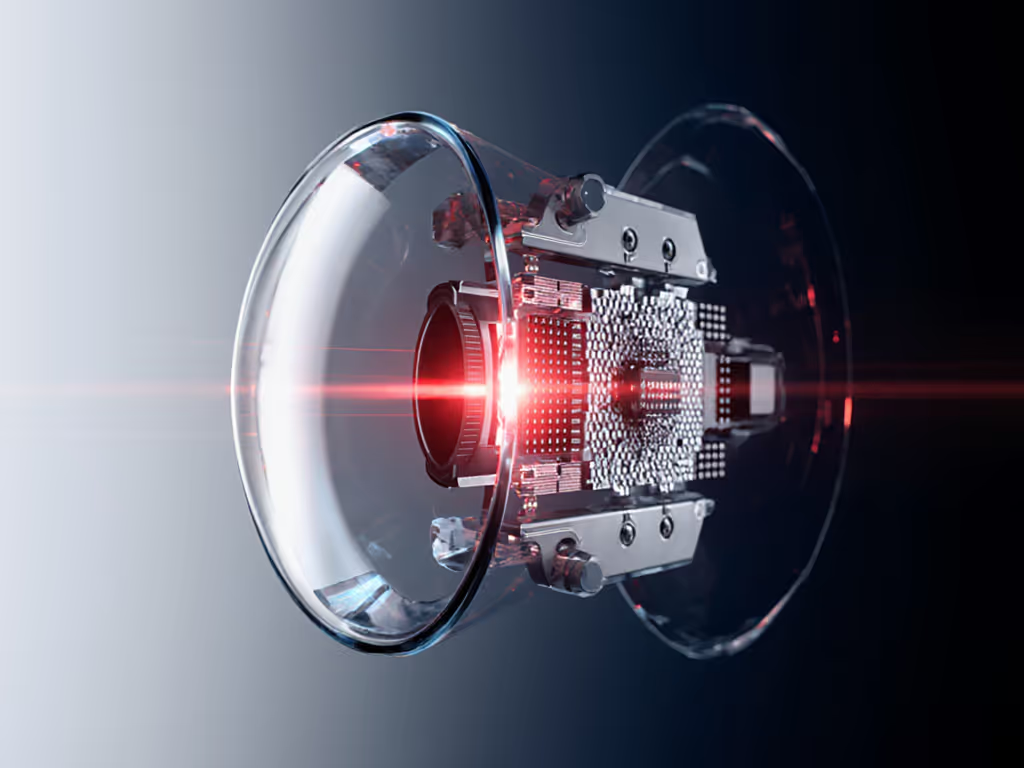

At their essence, modern mouse sensors are miniature optical tracking systems. Unlike the mechanical ball mice of the 90s, today's sensors use light and rapid image processing to detect movement. Here's the step-by-step breakdown:

- Light Source Activation: An LED (for optical sensors) or laser diode (for laser sensors) illuminates the surface beneath the mouse

- Surface Imaging: A CMOS sensor captures thousands of microscopic surface texture images per second

- Pattern Recognition: A dedicated DSP (Digital Signal Processor) analyzes consecutive images

- Movement Calculation: By comparing slight variations between images, the sensor determines direction and distance moved

This process happens at astonishing speed, typically 1,000 to 8,000 times per second (measured as polling rate). For a deeper dive into how DPI and polling rate affect real-world performance, see our DPI and polling rate guide. Each "snapshot" spans just 59 microseconds, with the sensor only tracking the difference between images rather than storing full frames. This efficiency enables precise tracking while minimizing power consumption, especially crucial for wireless models.

Optical Sensors: Precision Through Simplicity

Optical sensors represent the most widely adopted technology in modern mice, and for good reason. They use red or infrared LEDs to illuminate surfaces, creating a consistent light source that works exceptionally well on most desk surfaces.

How Optical Sensors Excel

- Surface Compatibility: Perform reliably on standard mousepads, wood, and cloth surfaces

- Stable Tracking: Less prone to acceleration artifacts that plague some laser sensors

- Power Efficiency: Lower energy consumption translates to longer battery life in wireless models

- QC Consistency: Manufacturing processes have matured, resulting in fewer batch-to-batch variations

When searching for the best mouse optical sensor, look beyond the maximum DPI rating. Real-world testing shows that sensors like PixArt's PMW3389 and newer iterations deliver exceptional tracking at moderate DPI settings (800-3200) where most users actually work. These sensors maintain consistent performance without the "jitter" that can occur when pushing laser sensors to their maximum specifications.

Laser Sensors: High DPI With Caveats

Laser sensors use a focused laser beam instead of an LED, penetrating deeper into surface textures. This creates both advantages and disadvantages compared to optical sensors.

Where Laser Sensors Shine

- Glass/Slick Surface Compatibility: Can track on surfaces that confuse optical sensors

- Higher Maximum DPI: Often rated at 8,000+ DPI compared to optical's typical 4,000-16,000 range

- Specialized Use Cases: Beneficial for graphic designers needing ultra-fine control on high-resolution displays

Critical Limitations

- Surface Artifacts: The deeper penetration can cause tracking issues on certain surfaces as microscopic details get misread

- Acceleration Issues: Higher likelihood of cursor acceleration that gaming and precision work cannot tolerate

- Increased Power Consumption: The laser diode requires more energy than an LED

When conducting laser vs optical sensor comparisons, lab tests consistently show optical sensors deliver more consistent 1:1 tracking (the holy grail for competitive gamers and precision workers). Laser sensors often introduce microscopic jumping as they over-analyze surface textures, creating what gamers call "jitter."

Understanding DPI Meaning in Practical Terms

DPI (dots per inch) represents how many screen pixels the cursor moves when you physically move the mouse one inch. But here's where marketing gets slippery: a 25,000 DPI rating doesn't necessarily mean better performance.

The Reality Behind DPI Numbers

- Diminishing Returns: For most users, DPI settings above 3,200 provide no tangible benefit

- Sensor Quality > Maximum DPI: How consistently a sensor tracks at lower DPI matters more than its maximum rating

- Software vs Hardware DPI: Some mice artificially inflate DPI through software smoothing, creating inaccurate tracking

In my years analyzing mouse tracking technology, I've found that sensors with exceptional signal-to-noise ratios at moderate DPI settings (1,600-3,200) consistently outperform those chasing headline-grabbing maximum DPI numbers. Gaming professionals and designers I've consulted rarely exceed 1,600 DPI in actual practice, proof that marketing often overshadows practical utility.

Longevity and Quality Control Factors

Sensor technology doesn't exist in a vacuum. The surrounding components and manufacturing quality significantly impact real-world performance. After tracking QC variance across dozens of models, I've observed:

- Sensor Housing Quality: Poorly secured sensors can shift over time, causing tracking inconsistencies

- Lens Clarity: Dust accumulation or low-quality lenses degrade performance faster than the sensor itself

- Circuit Board Design: Inferior grounding can introduce electrical noise affecting tracking accuracy

Remember that premium isn't always proportional to longevity. I learned this the hard way when a $120 "pro" gaming mouse developed double-click issues after three months while its $50 midrange counterpart survived daily travel for two years. My cost-per-month math revealed the cheaper option actually delivered half the ownership cost.

This experience reinforces my core principle: you should always pay for performance, not paint, packaging, or promises. Sensor performance matters, but so does the entire ecosystem: the circuit board quality, lens construction, and manufacturing consistency determine whether your tracking remains reliable over months and years.

Plain Verdict: Which Sensor Technology Wins?

After analyzing sensor specifications, real-world testing data, and long-term durability patterns, my QC-aware assessment delivers this clear verdict:

For gamers and productivity professionals, optical sensor technology provides the most reliable 1:1 tracking with better surface compatibility and consistent performance across different environments. The slight surface limitations (glass, mirrors) are outweighed by superior tracking stability on the surfaces where most work actually happens.

For specialized users needing glass tracking, modern high-end optical sensors have largely closed the gap. Only consider laser technology if you have a documented, recurring need for glass surface tracking that newer optical sensors can't handle.

The most important factor isn't optical versus laser, but understanding your actual needs versus marketing hype. Pay for performance where it matters: consistent tracking at your preferred DPI, not inflated maximum specifications that serve no practical purpose.

When selecting your next mouse, prioritize models with transparent sensor specifications, proven QC history, and clear warranty terms covering sensor failures. Your productivity and enjoyment depend more on sustained performance per dollar than launch-day specs.